How to Replace Watts Boiler Feed Valve

Pressure Reducing Valve Water Feeder Installation

Pressure Reducing Valve Water Feeder Installation

Steps in installing an utomatic boiler pressure-reducer water feeder valve

- POST a QUESTION or COMMENT about heating boiler pressure reducing valves, water feed valves, check valves: operation and repair

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Heating boiler water feeder valve installation steps.

This article series explains hot water boiler (hydronic heat) pressure reducing valves and types of manual and automatic water feeder valves used on hot water heating boilers, including when and how to add makeup water to a boiler.

We also provide an ARTICLE INDEX for this topic, or you can try the page top or bottom SEARCH BOX as a quick way to find information you need.

How to Install an Automatic Pressure Reducing Valve / "Water Feeder"

The photos here show a modern automatic pressure-reducing water feeder valve on a hydronic (hot water) heating boiler - one of the safety controls which we discuss in this article.

The photos here show a modern automatic pressure-reducing water feeder valve on a hydronic (hot water) heating boiler - one of the safety controls which we discuss in this article.

Gurgling noises in heating water pipes, radiators, baseboards: clogged water feeder

Watch out: a clogged, damaged, or non-functional pressure-reducer water-feeder valve on a heating boiler can lead to abnormally low heating boiler water levels that in turn can cause gurgling sounds in water piping, baseboards or radiatiors, and ultimately to loss of heat or even damage to the heating boiler. Here is an example:

After I was unable to figure why the furnace had a low water level that led to gurgling in the radiators, I decided to change the auto-fill valve above the expansion tank. I'd already changed the tank the week before but decided to cheap out and reuse the old valve.

When I disconnected and upended the tank/valve it spilled a bunch of black sulfur laden water out. The sulfur flakes may have clogged the screen or valve for as much as several years. - M.F. 12/24/2014

Boiler Water Feeder - Pressure Reducer Valve Installation

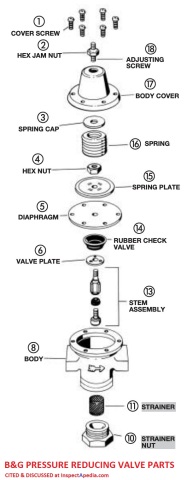

The following advice is adapted from Bell & Gossett's Instruction Manual V55999 Rev. M. Reducing Valves Installation & Service Instructions - a booklet that the installer is supposed to have been left for home owner use.[4]

Select the Proper Pressure Reducing Valve

There are multiple B&G pressure reducing valve models, not to mention competing valves made by other manufacturers. Valves vary by their pipe diameter (1/2" or 3/4"), connection type (union or NPT/Sweat), and by factory setting and adjustable pressure range. The latter two key parameters are pretty simple as there are 2 ranges:

- Factory set water feed pressure: 12 psi, with adjustable range of 10 psi to 25 psi (typical use on residential heating boilers)

- Factory set water feed pressure: 45 psi, with adjustable range 25 psi to 60 psi (you won't use this on a typical residential heating boiler)

Pressure Reducing Valve Specifications

- The maximum flow rate for these pressure reducer valves is 5 1/2 to 6 gpm presuming input pressure of 125 PSI - which is higher input than found at most homes.

- The maximum operating temperature for these pressure reducers is 225 °F.

- The maximum working pressure for these pressure reducer valves is 125 psig.

Pressure Reducer Valve Installation

Install the Pressure Reducer Valve Right side up:

Watch out: while some pressure reducer / water feeder valves work in any position, some models such as B&G's "Fast-Fill" pressure reducers must be installed in an upright position. What's "upright"?

Point in the right direction: The cast-arrow indicating direction of water flow must be in a horizontal position (and of course pointing towards the heating appliance).

Feed with cold water: We suspect that on occasion a plumber may supply the valve with hot water, thinking s/he is reducing the risk of damage that can happen by feeding cold water into a hot boiler.

While the installation instructions don't explicitly say so, the illustration provided by the manufacturer shows that the pressure reducer / water feeder valve that is going to supply water to a heating boiler is itself fed by the cold water supply piping in the building. And the manufacturer's instructions consistently refer to supplying cold water to the equipment, for example:

Open the cold water fill valve to allow the system to fill until the preset pressure of the valve has been obtained.

Install a water shutoff valve on the inlet (water supply side) of the pressure reducing valve.

Install a bypass valve and piping arrangement for fast filling of an empty heating boiler if the pressure reducer valve model you're installing is not itself a "Fast Fill" model.

Watch out: if you install a bypass valve to allow fast filling of the heating boiler, make sure that this bypass is closed during normal boiler operation. Otherwise the boiler will be over-pressurized, the relief valve may spill, equipment or the building may be damaged, the equipment may be unsafe.

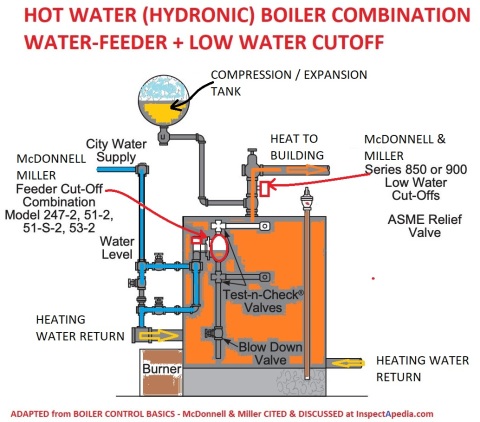

Install other safety controls: B&G recommends for safe boiler operation that a low water cutoff valve (LWCO), adequate burner safety controls (cad cell sensor etc), and a properly-installed float-operated water feed valve should all be installed. We are seeing more LWCO's installed on both hydronic and steam boilers, required by code in some jurisdictions.

And it's rare to see a modern steam boiler that does not have the recommended automatic float operated water feeder. Without these controls, and without appropriate air controls (air purger and thermal expansion compensation), B&G warns that the boiler may not work properly nor safely.

Don't over-do the pipe joint compound: the manufacturer warns to use pipe joint compound sparingly (not "the bigger the blob the better the job" as Dan B. Martin used to say).

The concern is that excessive pipe dope oozes into working control parts and can prevent safe, proper operation of the equipment.

Warning when using teflon tape on threaded pipe fittings: the same manufacturer warns that use of Teflon impregnated pipe compound and Teflon tape on pipe threads provides so much lubrication that it's easy to over tighten and damage the parts - risking unsafe or damaged equipment.

Indeed we found that when tightening a part such that we are approaching the part's desired final position, the lubricant effect of teflon can cause you to turn the part too far - so you're tempted to turn it for another complete rotation to get it where you want - followed by breaking the part.

Disassemble some parts when "sweat fitting" (soldering) them in place: when installing a reducing valve using soldering, to avoid damaging the valve by overheating it, first sweat the union connection fitting onto the system piping, then connect it to the valve.

Water feed pressure adjustment - at initial installation

When the pressure reducing valve installation is complete and you are ready to fill the heating boiler, open the cold water fill valve to allow the system to fill until the preset pressure of the valve has been obtained. (Residential pressure typically starts at 12 psi cold).

If you are using a Fast Fill model pressure reducing valve, instead of filling the system through the bypass valve and piping you lift the fast fill lever to the vertical position, overriding the pressure regulating features of the valve and allowing water to enter the heating equipment and piping at building water supply pressure. So be sure to stop filling when pressure in the heating system is at the proper cold-water temperature pressure.

If you are using a Fast Fill model pressure reducing valve, instead of filling the system through the bypass valve and piping you lift the fast fill lever to the vertical position, overriding the pressure regulating features of the valve and allowing water to enter the heating equipment and piping at building water supply pressure. So be sure to stop filling when pressure in the heating system is at the proper cold-water temperature pressure.

Watch out: after this initial boiler fill-up, close the fast fill lever - don't leave it up - open or the system will be unsafe and possibly damaged.

For pressure reducing valve feed pressure adjustment to meet varying building conditions such as tall structures that need higher starting pressure, see the detailed explanation found above in this article.

Watch out: The manufacturer warns that

The Bell & Gossett Pressure Reducing Valve is designed for filling hot water boilers and associated piping systems to a properly controlled pressure after boiler installation or system servicing. It is not a safety device and is not intended to be used as a water feed valve to control boiler water at a safe operating level. They are factory set at specified limits although adjustment is easily made. They are equipped with a built-in strainer and low inlet pressure check valve.

Pressure Reducer & Flow Control Valve Manuals

- Bell & Gossett SERVICE PARTS CATALOG [PDF] (2011) Bell & Gossett (a Xylem brand), Xylem Inc. 8200 N. Austin Avenue Morton Grove, Illinois 60053 Phone: (847) 966-3700 Fax: (847) 965-8379 www.xyleminc.com/brands/bellgossett replacement parts for B&G circulators, Flo-Control® valves & other B&G products.

B&G pressure reducing valve repair parts are found on p.38 in this catalog.

- B&G Flo-Control Valves - installation, operation, and service instructions manual [PDF] original source Bell & Gossett, 8200 N. Austin Ave., Morton Grove IL 60053, USA - Tel 847 966-3700 Fax 847 965-8379 . www.bellgossett.com/BG-Literature-Detail.asp?LiteratureID=607

- B&G / ITT Reducing Valves, Instruction Manual V55999: Reducing Valves Installation, Operation, & Service Instructions [PDF] Bell & Gossett Air Separators and other heating system components, Bell & Gossett, 8200 N. Austin Ave., Morton Grove IL 60053, USA - Tel 847 966-3700 Fax 847 965-8379. Original source www.bellgossett.com/literature/files/610.pdf

Reader Comments & Q&A

To be clear, in the U.S. ASME does not require that a LWCO (low water cutoff) float type control be installed on residential hydronic (water not steam) boilers; the International Mechanical Code (IMC) does want to see a LWCO on all boilers, both steam and hydronic. You can find LWCOs and water feed devices from various manufacturers including McDonnell & Miller.

The illustration above is adapted from McDonnell & Miller's HEATING BOILER BASIC OPERATION [PDF] McDonnell & Miller, retrieved 2019/11/06 original source: https://www.controlcomponents.com.au/Open-File/557/Boiler%20control%20basics.pdf

and can also be downloaded free from InspectApedia.com at the live link just above.

Oh ok

Oh ok

BTW for other readers, the pressure/reducer/water-feeder used on residential boilers does not really regulate the boiler pressure except insofar as the feeder will add water to the boiler if the boiler pressure falls below 12 psi (or other settings if the device has been adjusted or modified).

At the other end of boiler pressure, on a residential boiler the temperature/pressure relief valve will open and spill water (and pressure) if boiler pressure exceeds 30 psi.

So together those two devices manage the high end and low end pressures of the boiler.

The combination of starting water pressure in the cold boiler and the temperature to which the boiler rises are the main determinants of the actual operating pressure in the system - normally ranging between about 12 psi and under 30 psi. It's the aquastat that controls boiler temperature.

WATER FEEDER VALVE, STEAM illustrates the float controlled valve on a STEAM boiler - less common on residential boilers.

In North America and many other countries a residential hydronic boiler's water supply is controlled simply by an automagic boiler feed valve, and where required an additional backflow preventer to protect the water supply system piping - such as this Watts boiler feed valve (below)

Around our location in Mexico the same solar water heaters as your Costa Rica unit are very widely used.

- Glad to be of help from across our president's wall

Thanks so much, really enjoying this!

As for: "won't regulate the temperature properly" - brain fart - meant to type 'pressure' not 'temperature' and missed it on the proof-read! Got the gist.

I repaired a leak in my radiator system on my Jeep Grand Cherokee (1998 5.9 Limited) with White Pepper - made a poultice and spooned it in - lasted for 60,000 miles+ until I sold it!

inspectapedia.com is such an excellent resource - 5 outta 5 on Trip Advisor ok?! Lol, too bad.

So a float-controlled water feed valve is in my future - I have one of those on the Chinese Solar Water Heater that I installed on my roof in Costa Rica :-)

As a retired JM Boilermaker/JM Boilermaker Welder (36 years) I'm still learning! This is small stuff compared to what I'm used to in my trade (ie 10" water feed piping, 72" gate valves, etc) but it's all working under the same principles of course. Back to my own personal house boiler.

Regarding the leak - don't believe I'll find it so I'm going to carry on as is. The tradesmen searching for the leak previously removed nearly all the insulation from the piping which is very unfortunate - and there is evidence of scale and deposits buildup at multiple locations, but nothing wet.

The town we live in switched to a full R/O system about 10 years ago so the scale issue is done at least (particularly for build-up inside the pressure regulator on the screen).

From the calculations on the other page (multiply feet of rise by 0.43 and add 3#) I have determined that I should only need about 10# pressure to feed the 2nd floor radiators.

I'm going to let the pressure drop now until the radiators are cold on the 2nd floor and I'll know where the "sweet" spot is for certain. Any danger in this? Is a vacuum created when the pressure drops too low?

You said: "While the manufacturers are careful to say that the pressure/reducer/regulator should not be used as an automatic water feeder, that's what almost everyone relies on in residential hot water heating systems."

"a properly-installed float-operated water feed valve should all be installed."

Thanks again for you time and trouble - please take a moment to answer my two questions above.

Reader comment:

(Oct 27, 2014) Zach said:

Thanks, this was really helpful as I work on my home boiler system.

Question: why do I have to keep adding water to my boiler?

(Jan 16, 2012) Bob said:

why do i have to add water daily to my boiler

Reply:

Bob:

If you are having to add water to your boiler too often either there is a leak somewhere (a condensate line, or hidden in the boiler itself), or steam vents are not closing when they should. Or an automatic water feeder on your system is not working.

Question: expansion tank (or relief valve) keeps discharging water as service water pressure varies

I have a gravity feed system with water radiators in my home. When I leave the incoming water on the pressure in my system goes sky high the expansion tank discharges the water. When my system is full of water and I turn off the incoming water by the water feeder my system loses pressure and I have to add water again thru the water feeder. Is my water feeder the issue?? When the system loses pressure where is that water going?? The expansion tank is above my furnace in my basement. Any help would be appreciated!! Thanks, Fred

In regards to my gravity feed system "pressure" problem question -- Municipal water, system has been working fine for last 15 yrs. When system full of water home heats fine but when furnace off pressure drops. Thanks, Fred

Reply:

Fred,

Particularly with a gravity circulating system, that is you rely on hot water rising through the heating pipes by convection rather than by using a circulator pump, if there is not enough pressure in the heating system hot water may rise too slowly or even not at all to upper floors in the building.

Check the water pressure in your heating boiler (furnaces are hot air systems, water based heating systems are boilers) when the system is cold - for a typical 2 story home you'll want to see 12 psi cold pressure in the boiler.

If your boiler pressure is low and/or if you've had a leak and lost boiler water leading to low pressure AND if your water feeder valve is not working properly (or is not properly set) then you may have low boiler pressure.

Also take a look at "What is the proper water pressure setting for a pressure-reducing valve or water feeder valve on a Hot Water Heating System?" in the article above.

Question: My house is too hot and the boiler circulator keeps going even if I turn down the thermostat

The circulator pump on my Weil Mclain boiler doesn't respond to the thermostat. I closed the manual flow valve to prevent the baseboards from "heating" during the summer. I recently had to open the valve to provide heat to the house now that it has gotten colder but when the house heated up too hot the flow valve would not close and the baseboards continued to receive hot water.

How can i "fix" the valve to shut off the water supply to the baseboards? Will i need to purge the water from the zone to replace the valve? - House too hot 12/21/11

Reply:

House too hot:

You're asking a question under an article on automatic water feeders -- valves that maker sure the water in a heating boiler is kept at proper level. This won't help you with a heat control issue.

Under BOILERS HEATING (links at the ARTICLE INDEX the bottom of this article ) you'll

see BOILER CONTROLS & SWITCHES - an article that lists various boiler controls. Your control problem could be in any of several places

- the wall room thermostat -

see THERMOSTATS, HEATING / COOLING

- the circulator control and relay switch (good guess) -

see CIRCULATOR PUMPS & RELAYS

- and the flow control valve - which should act as a check valve to prevent hot water from circulating up out of the boiler when you are not calling for heat -

see CHECK VALVES, HEATING SYSTEM.

Fixing the problem by opening and closing the flow-control valve is a stopgap that as you have seen, is not a great solution.

Your system may have two faults:

1. the hot water should not be circulating out of the boiler in summer when you never call for heat - this is a flo control valve problem, presuming that there is some reason that the boiler is hot in the first place (like keeping it hot for making domestic hot water)

2. the circulator not responding to the thermostat - sounds like a circulator relay control problem, presuming that it used to work and that no one changed the wiring.

To replace a flow control valve or some circulator pump assemblies that are plumbed directly in line in the hot water heating system, unless there are isolating shutoff valves before and after the device, you'll need to cool down the system, drain the affected piping, replace the part, and indeed, purge air from the lines to restore heat.

Keep us posted - what you learn will help other readers.

Question: Top floor radiator is not getting water - should I up the system pressure?

I have a home with 3 levels above the basement, and radiators on every floor. The radiator at the very top floor does not seem to even contain water, and bleeding does not help. The radiators on the 2nd floor, just below the attic used to heat up fine, but now they do not seem to have water either. Obviously, there is a pressure issue here, but I had the water feeder valve for my hydronic system replaced just 4 years ago.

The radiators in the basement and on the first floor work just fine. Can I turn the pressure screw on the water feeder to increase the pressure while the system has been operating for the past 2 months and the boiler is not cool? - Joey Butters 12/31/11

Reply:

Joey I would NOT start by changing system pressure since there is a good chance that your top floor radiator is simply air bound. Hop over to our radiator troubleshooting articles at RADIATORS and you'll see how to check for and fix an air-bound heating radiator by simply opening an air bleeder.

Question:

i have a three zone ( individual circulator pumps) hydronic system that i recently changed the expansion tank and auto bleeders on and now it wont keep pressure for more than an an hour or so i have searched the system for leaks and cant see any. i have to keep adding water to get pressure back.

what else could be wrong and can i leave the make up water valve (not the pressure reducing valve) but the one that feeds it open? is this dangerous?? it is a two story house - Martin Griffin 1/15/12

Reply:

If the system is not maintaining pressure we need to look for a leak or a defective backflow preventer or check valve.

Question: The relief valve at my boiler keeps leaking, even after we replaced it

My boiler has been leaking at the pressure relief valve for 1 week, with the pressure at 30-35 when hot. I drained the steel expansion tank fully, and then re-started the system. The pressure initially was back down around 20, but within 1 day was back up in the 30s and leaking at the PRV. I had a technician come and install a new pressure reducing valve. We all thought that would fix everything.

We drained the expansion tank again before re-starting the system. After we re-started the system, the pressure continued to rise. one day later we're back at 33 PSI and draining from the PRV. I tried draining more water from the expansion tank and closing of the water valve from the city. The pressure in the system went down to 20. After running the heat, it's now hot and at 25 psi. Could I have just gotten a defective new pressure-reducing valve? Any thoughts? Help would be appreciated. - Josh 2/7/12

Reply:

Great question Josh. There are actually several things that can cause the relief valve on a boiler to leak, among them is an automatic water feeder/pressure reducer that is not working properly, but there are quite a few other causes too. The fact that you drained your expansion tank and then found that you could drain it again makes me suspect that as the best starting place.

If it's an older bladderless type expansion tank (some call these compression tanks) it may be that it wasn't adequately drained. If the expansion tank is a newer type that has an internal bladder the bladder may be damaged or the air valve may be leaking out the air charge. Details are

at EXPANSION TANKS.

At RELIEF VALVE LEAKS we provide a catalog of all causes of leaks at all types of pressure or pressure / temperature relief valves.

Also see RELIEF VALVE, TP VALVE, BOILER if your boiler is a steam boiler,

or if yours is a hydronic (hot water) system

see RELIEF VALVE, TP VALVE, STEAM BOILER

Question: the water level in my steam boiler keeps rising

my sight glass on manual feed boiler rising without adding water I have steam heat system with

an indirect water heater. - Anon 2/23/12

Reply:

Anonymous:

Your water feeder valve may need repair or replacement. Review the diagnostic text in the article above. This is particularly likely if the boiler level is actually increasing. Don't confuse increased boiler water level with surging when the steam boiler is heating up.

And don't forget to double check that someone else has not manually added water to the boiler.

Question: where do I add water to my furnace

Need to know where I add water to my furnace. The low water indicator is on. Not sure where to look. And not sure if I have an automatic water feeder. Thank you LJV 109/23/11

Reply:

LJV

Indeed finding where to add water to a steam boiler can be tricky for an unfamiliar building owner because the water supply valves are not always located in the same place.

Try backing up a bit: find the cold water supply piping in your home. Follow the piping to the steam boiler.

That route will show you where water enters the boiler as the piping will end either at a manual valve, at an automatic water feeder valve, or at a combination of the two - that is, some boilers may include an automatic water feed valve as well as a manual valve located on a piping loop that pipes around the water feed valve.

In the links listed at the ARTICLE INDEX the bottom of this article , under STEAM HEATING SYSTEMS

be sure to read the following two articles:

LOW WATER CUTOFF CONTROLS

Water Feeder Valves, Steam

Those articles include photos of the valve(s) you are looking for.

Or use the CONTACT link at the ARTICLE INDEX the bottom of this article to send me some sharp, well-lit photos of your system and I'll be glad to look them over and give more specific advice.

Question: is it ok to turn off the water supply to the heating boiler in winter?

(Sept 30, 2014) Anonymous said:

can a hotwater boiler be operated w/out make up for 2 months during cold weather

(Nov 29, 2014) DAN D. said:

Going on vacation for 2 months and wondering if it's OK to shut the cold water supply line to the hydronic water heater. This would still allow all the circulation etc but allows me to shut down the main water supply to our house. This system supplies heat to our lower floor only

. I would like to shut the water main off to my house while away. The hydronic heater is separate from the domestic hot water heater. If OK then the heat would still be available but I would not have the potential problem of water leaks from the plumbing system components such as a cracked toilet tank etc.

Thanks for any comments

Reply:

It depends, Anon.

If you mean a steam boiler, almost certainly not - the risk is loss of heat or boiler melt-down or worse.

if it's a hydronic (hot water) heating boiler, maybe, if there are are no leaks. But there too if the boiler leaks it could be destroyed or cause very serious damage to the building if the boiler lose heat or explodes from loss of water. If the boiler has a low water cutoff safety valve (as is installed on all steam boilers) then you'd hav some protection from the latter castrophe.

Dan

I sometimes shut off the water main to a home heated by a boiler but *only* if I am very confident that the system is bullet proof and leakproof - the worry is that a leak in the system can destroy the boiler or even lead to a fire.

If the boiler has a low water cutoff valve on it then you're safe: it will simply shut down if it loses water.

Otherwise I would leave water on to the boiler.

In some buildings it's possible to leave the water supply on to the boiler but to shut off all of the hot and cold water supply piping to the rest of the house. That reduces the freeze-burst-pipe damage risk substantially and is worth doing.

Dan see this recent article we put together on this at

WATER TURN OFF? - see inspectapedia.com/plumbing/Winterize_Turn_Water_Off.php

More details about this topic are at our WINTERIZE HEAT ON article found at inspectapedia.com/plumbing/Winterize_Heat_On.php

Question: What valves do I need on my boiler: why do I have no heat in half of my baseboards?

(Nov 18, 2014) Jeqal said:

I have a boiler with two spigots and two silver valves. How do I know which one is the drain and which line the two valves go to? The copper pipe is in a circle at the boiler and one of the handles is at the top and one is upside down on the bottom (the valve is a circular dial style handle). I am not receiving heat to half of my base board heat. Do I need to turn one or the other valves? How can I check it?

Reply:

Jeqal

From just your note, I don't know what valves you are referring to.

Check that each room thermostat for each heating zone is calling for heat - set the thermostat well above room temperatures.

Then check that the boiler is circulating hot water in each heating zones - touch or feel (with care) for hot pipes at each circulator or zone valve.

There could be a thermostat, zone valve, check valve, or even an air bound heating system problem.

It's time to call your heating service technician.

Question: how do I know if a water feed valve or TP relief valve is bad?

31 Jan 2015 Anonymous said:

How do I know the feed valve or relirf valve are bad or replace both the relief valve is letting water out. I have a new expansion tank

Reply:

Anon

If you are seeing leaks from the water feeder valve chances are it needs repair or replacement; some water feeders can be repaired using a re-build kit.

But

Watch out: when you also cite that the relief valve is leaking that suggest that either the heating system is at too high a pressure or temperature (unsafe conditions that deserve a system shut-down) or the leaks could be caused by a water-hammer problem at the building or high water pressure or both.

First see RELIEF VALVE LEAKS

then

See WATER HAMMER NOISE DIAGNOSE & CURE

Question: normal input pressures

(Feb 12, 2015) Anonymous said:

my psi rteads 40 on water inlet gauge. is this too high

Reply:

40 psi is within normal building water supply service pressure ranges.

About water pressure: 40 psi on the street side of the pressure reducer/water feeder valve side of a feed valve for a boiler is ok.

Watch out: But if you are seeing 40 psi on the boiler side, such as on the boiler's gauge, something's wrong and if that's really the pressure you should shut down the system as it is unsafe.

Question: can't get water to boiler after flush-out

(Feb 24, 2015) Anonymous said:

I shut down boiler and flushed it . When I turned it back on not getting water to boiler

Reply:

Anon

Check for a debris-clogged fill valve. Try lifting the valve bypass lever to see if that sends water to the boiler.

Question: recurrent air blocked radiators, low psi water feeder

16 March 2015 Tony said:

I have a issue with my 4 story building in NYC, top floor, 4floor, (2) apartments have alot of air trapped in the radiator. I installed auto vent valves and still not helping. I force water thru the auto water feeder and that forces the air out of the line and it is fine for a few days. Then air gets trapped again.

I have to force water every 3-5 days during this winter. I believe that my water feeder psi is set at 15 psi. I don't believe it is enough pressure. Based on your input, I may need a different type of auto water feeder, more for commercial. Every winter we have this issue and not sure what to do next. I tried to get multiple plumbers to look into this matter and they have no idea. Based on your carlson dunlop diagram, I need 20-30 psi pressure for a 4 story building. Please advise it will be greatly appreciated.

Reply:

Tony, what you say sounds reasonable to me. If you are seeing recurrent air blockage in all of the radiators of both top floor apartments that strengthens the argument.

What does your heating service company technician say about the water pressure settings?

...

Continue reading at WATER FEEDER VALVE, HYDRONIC BOILER or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CHECK VALVES, HEATING SYSTEM

- LOW WATER CUTOFF VALVE, BOILER

- PRESSURE REDUCING VALVES

- PRESSURE REDUCING VALVE (BOILER) CLOG REPAIR

- PRESSURE REDUCING VALVE DISASSEMBLY

- PRESSURE REDUCING VALVE REPAIR KIT

- PRESSURE REDUCING VALVE WATER FEEDER INSTALLATION

- SIGHT GLASS, STEAM BOILER

- STEAM BOILER FLOODING REPAIR

- WATER FEEDER VALVE, HYDRONIC BOILER - forced hot water heat

- WATER FEEDER VALVE, STEAM - steam heat: yours is a steam boile

Suggested citation for this web page

PRESSURE REDUCING VALVE WATER FEEDER INSTALLATION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

...

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Comments & Questions are Welcome Here

If you posted comments here and no longer see what you wrote, please check for your comment in the Reader Q&A found above on this page.

Technical Reviewers & References

Click to Show or Hide Citations & References

Source: https://inspectapedia.com/heat/Pressure-Regulator-Water-Feeder-Installation.php

0 Response to "How to Replace Watts Boiler Feed Valve"

Post a Comment